| |

PaintFlex® Paint

Hard to Bond Plastic Painting

|

|

| |

Polyethylene Plastic Painting

|

| |

1) Rotational Moulded Polyethylene Plastic components Painting

|

|

| |

Polyethylene is by far the most common material used in rotational moulding, but it has traditionally suffered from the disadvantage that it cannot be reliably painted.

Although these polymers can be coloured using a tinted raw material, good control of final appearance has been impossible, precluding their use in very many applications. PaintFlex® have solved the problem.

|

PaintFlex® Unique Paint Technology, Almost no competitions

|

| |

PaintFlex® has the Paint technology which is unique in the World, which ensures you can get the precise finish you want on the Rotational Moulded Polyethylene Plastic parts.

|

Type of Plastics: LLDPE,MDPE

|

| |

PaintFlex® is an adhesion Paint that allows rotationally moulded polyethylene to be finished and prepares PE plastic for painting with any top coats like automotive 2K paint systems and Other Conventional Paints. High quality gloss results are now easily achievable with industry standard spray painting equipment. This technology now allows polyethylene products to be considered for applications previously unsuited to this material.

|

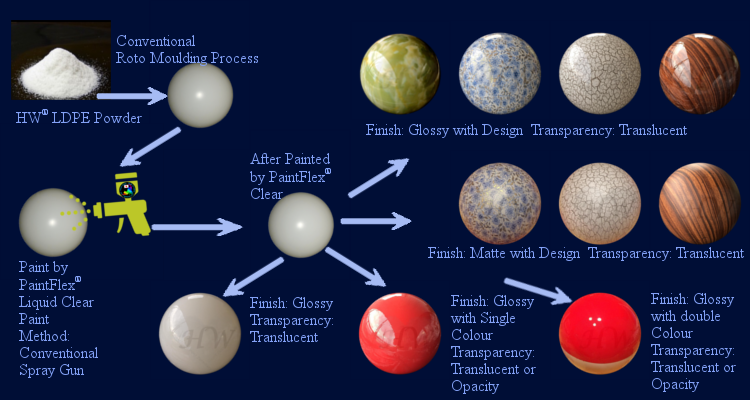

You can now have any of the following paint schemes on polyethylene rotomouldings

|

| |

High glossy Natural Finishing (Translucent and Non Translucent)

High glossy Colour Finishing (Translucent and Non Translucent)

High glossy Graphic Finishing (Translucent and Non Translucent)

|

Some Benefits for Roto Moulding PE

|

| |

Enhance the surface appearance like Pinholes

Pinhole Free Surface for hygienic: No accumulation of dust and dirt on the surface

|

Process & Finish

|

| |

|

| |

2) UHMW-PE and HDPE Polyethylene Plastic Board Painting

|

|

| |

UHMW-PE(Ultra high molecular weight polyethylene) is an extremely tough plastic with high abrasion and wear resistance. The versatility of polyethylene has made it a popular plastic for countless industrial applications that require durability, low friction, and chemical resistance. Applications including Outdoor Furniture ,Signage Board ,HDPE Boat and many other applications.

But it has traditionally suffered from the disadvantage that it cannot be reliably painted.

Although these polymers can be coloured using a tinted raw material, good control of final appearance has been impossible, precluding their use in very many applications.

PaintFlex® have solved the problem.

|

PaintFlex® Unique Paint Technology ,Almost no competitions

|

| |

PaintFlex® has the Paint technology which is unique in the World, which ensures you can get the precise finish you want on the UHMW-PE and HDPE Polyethylene Board Plastic.

|

Type of Plastics: PE-500 / PE-1000/PE-80/100/300

|

| |

PaintFlex® is an adhesion Paint that allows UHMW-PE and HDPE polyethylene to be finished and prepares PE plastic for painting with any top coats like automotive 2K paint systems and Other Conventional Paints. High quality gloss results are now easily achievable with industry standard spray painting equipment. This technology now allows polyethylene products to be considered for applications previously unsuited to this material.

|

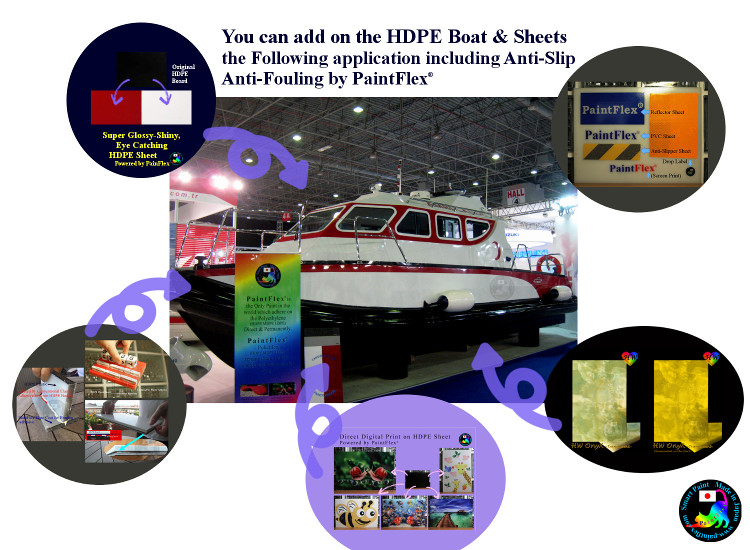

You can now have any of the following paint and Adhesion schemes

On UHMW-PE and HDPE polyethylene Board

|

| |

High glossy Natural Finishing (Translucent and Non Translucent)

High glossy Colour Finishing (Translucent and Non Translucent)

High glossy 3D Graphic Finishing (Translucent and Non Translucent)

High glossy UV-Flatt Graphic Printing Finishing (Translucent and Non Translucent)

Binding conventional Elastic Adhesives-Glue

Binding conventional functional top paint & Coatings like Antifouling, Anti slip and others

|

UHMW Polyethylene Board

|

| |

Polypropylene Plastic and Other Hard to Bond Plastic Painting

|

|

|

| |

PaintFlex® is an adhesion Paint that allows PP and PP-Glass Reinforced, PA6 and other Hard Bond Plastics to be finished and prepares PP plastic for painting with any top coats like automotive 2K paint systems and Other Conventional Paints. High quality gloss results are now easily achievable with industry standard spray painting equipment. This technology now allows PP products to be considered for applications previously unsuited to this material.

|

Some Benefits

|

| |

Not request Flame/Corona or other treatments for Adhesion.

Resistance to expand/Contract & Vibration.

Resistance to Peeling and cracking

UV Light ,Colour Fading Resistance

Scratching resistance

Power Wash resistance

Apply by standard painting tools.

|

| |

Compliances

|

| |

Food contact friendly

RoHS (Restriction of use of Hazardous Substances) Compliant

|

Some Technical information

|

| |

Properties:

Solvent base, Single component, No hardeners

No "pot life, Near Zero Waste", Extra-long shelf life like 5 year

It is a paint and Adhesion paint, not inhibitor or Primer.

Free of heavy metals: no lead, cadmium, chrome including Zinc, Isocyanate

|

|

|

|